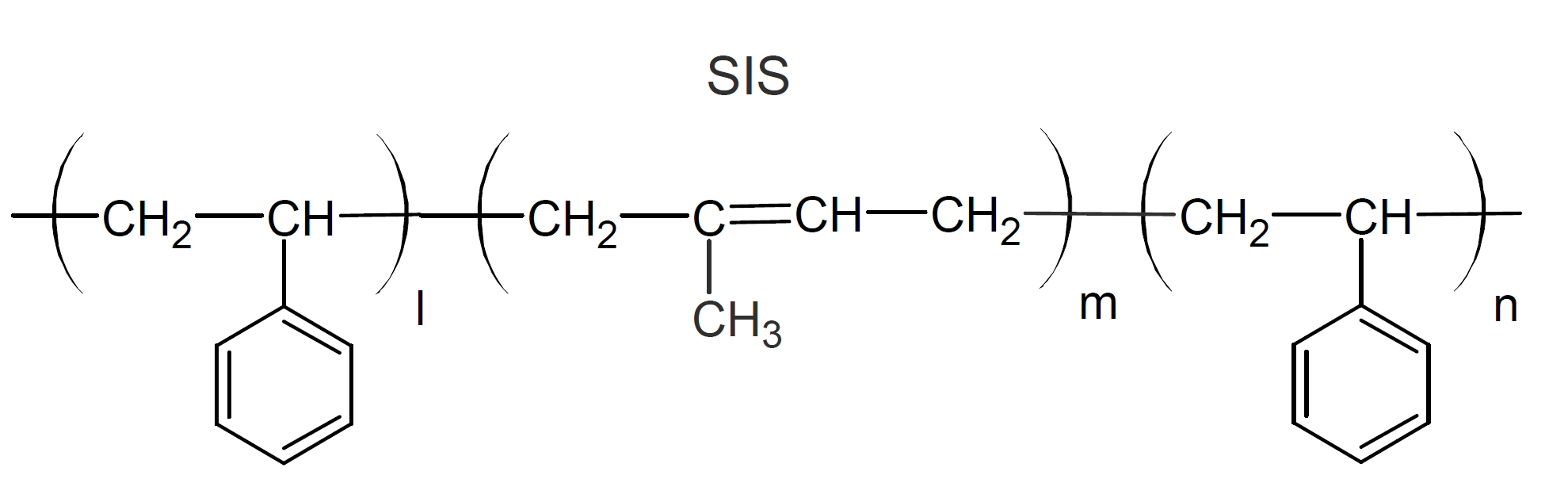

Styrene-Isoprene-Styrene Rubber

Properties and Applications

Styrene-isoprene block copolymers (SIS) are large volume, low priced commercial thermoplastic elastomers (TPE) which are produced by living ionic copolymerization by sequentially introducing styrene, 2-methyl-1,3-butadiene (isoprene), and styrene into the reactor. The styrene content typically varies between 15 and 40 percent. When cooled below the melting point, SIS’s with a low styrene content phase-separate into nano-sized polystyrene spheres imbedded in an isoprene matrix whereas an increase of the styrene content leads to cylindrical and then to lamellar structures. The hard styrene domains function as physical crosslinks which provide mechanical strength and improve the abrasion resistance, while the isoprene rubber matrix provides flexibility and toughness. The mechanical properties of SIS elastomers with a low styrene content are similar to those of vulcanized rubbers. However, unlike vulcanized rubber, SIS elastomers can be processed with equipment used for fabricating thermoplastic polymers.

SIS block copolymers are often blended with tackifier resins, oils and fillers, which allows for a versatile modification of product properties or they are added to other thermoplastic polymers to enhance their performance.

SIS copolymers are widely used in hotmelt adhesives, sealants, gasket materials, rubber bands, toy products, shoe soles and in bitumen products for road paving and roofing applications. They are also used as impact modifiers and tougheners in plastics and (structural) adhesives.

Manufacturers & Distributors

Companies |

Brands |